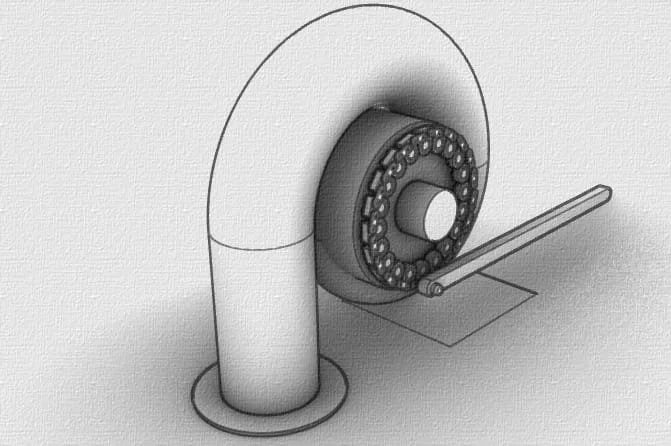

UGT Biogas Generator

BIOGAS FROM ANIMAL WASTE TO EXCESSIVE GARBAGE: “Methane”

Humans have used dried animal waste as a heat and fire source for hundreds of years. And methane gas has always been a byproduct. A century ago only small villages and rural areas used this heating method so CO2 was not an issue. But today with all the cattle, dairy, hog, and chicken farms that have developed worldwide, there are millions of tons of manure produced every day.

Biogas is caused by the decomposition of animal waste or from microorganisms found in garbage. Biogas is one of the major sources of CO2 being added into the air and increasing global warming. In fact, according to EPA estimates, just in the United States, food and animal waste alone (not counting landfills) release 170 million metric tons of CO2 annually, an amount equal to the CO2 generated by 42 coal fired power plants.

Authorities also estimate that landfills, food and animal waste, combined, are responsible for 40% of all global warming. In the past two decades scientists realized these facts and began dealing with the situation. They developed technologies that include creating energy by gasification systems, garbage burning, and even making burnable cubes for burning outdoors or in fire places. But unfortunately, these developments have not been enough and current methodologies cannot cope with amount of methane gas being generated, especially in the face of continued growth of farms, cattle raising and the depletion of oxygen producing forests.

About

The truth is that we just haven’t had the capability to significantly improve the situation. And it needs to be improved. The worldwide target is to not only eliminate or reduce this issue by at least 90%, but also turn the waste, heat and gases into clean energy while returning pure oxygen into the atmosphere.

With heat waves, drought, wildfires and extreme winters around the globe, it’s obvious that global warming is a problem and the world is in need of a solution. It has taken 6 years but UGT Tech has solved the problem with the UG Tech Biogas Generator.

UGT Tech has developed a biogas generator that not only takes biogas and turns it into usable energy but also returns the burned gas into the atmosphere as clean oxygen. Thus, biogas can cool our homes in the summer and heat them in the winter, a win/win result of providing cheap energy while reducing global warming.

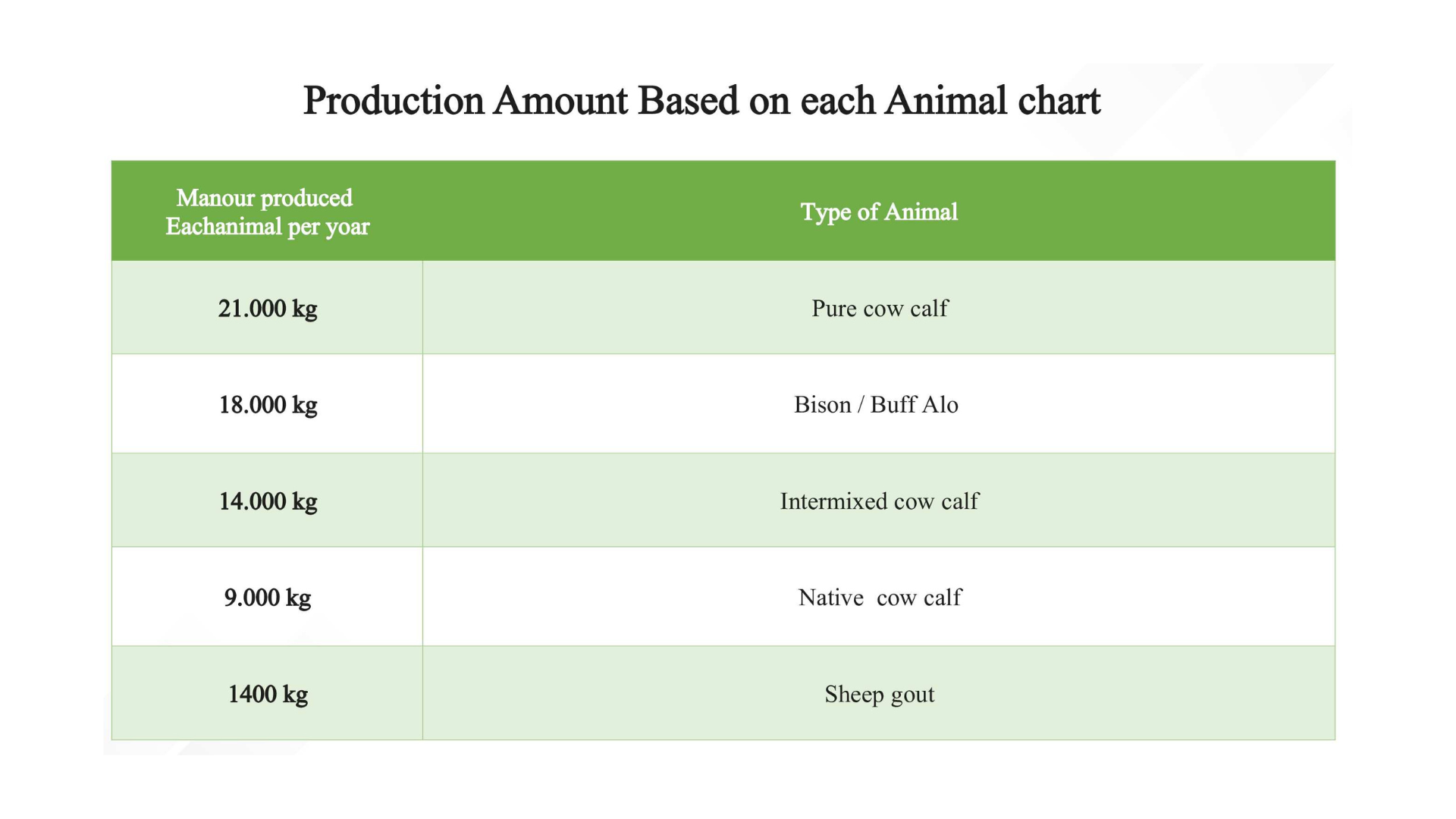

As an example of how this would impact the world, consider the application of UGT Tech Biogas Generators in the United States. With the manure from 100 million cows UGT Tech Biogas Generators can produce 12 tera watts of power daily. In addition, the systems can use the leftover material from its processes to establish and maintain vertical farms, plus provide fuel for camping instead of using charcoal. In terms of fossil fuel comparisons, it would amount to saving 1 million barrels of oil per day.

UGT Tech Biogas Generators can also serve the investment community by generating electricity that feeds into the power grid, thus paying for itself and returning a substantial return on investment. No other company offers this potential.

The benefits of UGT Tech Biogas Generators can impact users in a variety of ways. Farmers can be self-sustaining by providing their own power and selling the excess to the electrical grid as well as adding vertical farms to their product line. Landfills can also be self-sustaining and benefit from selling excess power generation. Both communities may also benefit from government programs which subsidize green power.

Overall it’s a win/win situation for humankind, converting a problem(Biogas) into a benefit (Power) and benefiting the world (Reducing global warming).

How the UGT Biogas generator works:

1) Waste matter enters the UGT generator receiving compartment where it is mixed with water to become a consistent liquid.

2) The liquid mix is moved to a second compartment and further combined with a variety of enzymes.

3) The liquid mix then moves to the main container tank where it begins breaking down as heat and air are applied, separating the gas.

4) When this gas reaches the required pressure, it goes through the filtration system to separate all impurities, and is dried.

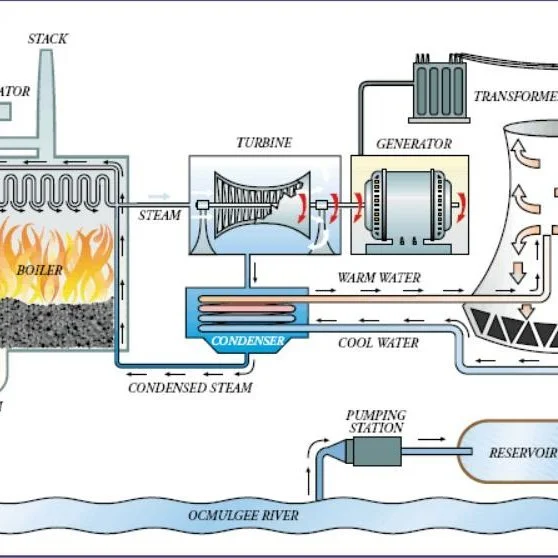

5) The pure gas then enters a special gas generator tank where it begins burning and generating electricity. The excessive heat creates approximately 35% more electricity than standard biogas generators.

Process

6) Separate from the gas, the enzymes go through fermentation and disintegration and move to another tank where the water is separated and purified while pressure is applied to the enzymes to convert them into dust to be used as fertilizer, or can be converted to burnable blocks similar to charcoal so nothing is wasted. Humidity of 10% to 20% is added to the dust when converting to blocks, which are normally 2 kilograms each.

To ensure no CO2 or other dangerous gas reenters the atmosphere the filter system is designed to capture any dangerous gases before entering in to the air, thus preventing damage to the environment.

So the leftover dust has two uses. It can be bagged and sold as fertilizer, especially for organic farms, or made into blocks and distributed as an alternative to charcoal or wood without the negative CO2 effluents. Alternatively, the blocks can be transferred to a boiler generator to be used as fuel.

The UGT Biogas Generator System comes in 3 versions:

1) Home use

2) Industrial use

3) Power plant use

Benefits

The benefits of the UGT Biogas Generator System:

1) Production of electricity and usable gas (for home immediately upon installation).

2) High efficiency of generating biogas, .5 meter square of gas per kilo of manure.

3) High efficiency gas motor and generators.

4) Lowest price on the market.

5) Sterilized fertilizer

6) Clean burning fuel blocks

7) Clean water.

8) Return on investment from sales of excess power.